© 2009 - SSJS, Sei Do Kan Dojo All rights reserved.

Review & Cutting Test Hans Fricke Kyoshi, February 2010

Having read much about the Raptor's quality and cutting-power on the Internet and for having been specially designed for tameshigiri, we could not resist to buy a couple of those katana for general dojo use, and with a price tag of just under AU$500, we thought 'What the hell - let's do it". So, did we make the right decision?

The Raptor comes with a sword bag, a sageo and a couple of info sheets; how to make the habaki fit into the koiguchi and one on general blade maintenance and an other giving general info on Hanwei products.

Mountings.

The overall first impression is one of quality - till one unsheathes the blade. The saya is well made and in a brown mottled lacquer finish. The tsuka is inlaid with same and wrapped in a sued like material that feels like leather. The tsuba, in my opinion, could have been a bit smaller as this would have lend a bit more elegance to the katana. The fuchi kashira are all of the same Raptor theme and fitted tightly. The tsuka-ito is tight but, after a dozen cuts, showed some movement on the top of the handle

(1).

The Blade.

The blade, even for an entry level blade, in my opinion, shows poor workmanship and its machine finish, in comparison to other blades in a similar price range, is sub-standard. Also the claim, quote "the sword was made to be a high performance cutter first and foremost" does not ring true here also, especially after the blade performed poorly in our test-cutting comparison on hard tatami-omote and green 40-45mm bamboo take.

Shinogi

ridge-line.

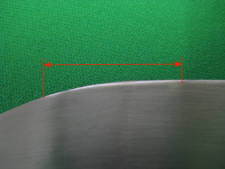

The shinogi ridge-line that separates the upper surface shinogi-ji from the lower face of the blade ji should always be crisp and clearly defined and not as wavy and untidy as on the Raptor Shinogi Zukuri

(2).

JI

blade surface.

(3)

The ji is the surface below the shinogi-ji and as it's the one that comes into close contact with the target material during a cut, and to reduce drag to an absolute minimum, must be perfectly smooth. On the Raptor Series Shinogi Sukuri this surface has only a rough machine finish with the lines running parallel to the cutting edge

(a),

acting like a piece of sand-paper and, due to the high friction created, slowing the blade down considerably. As mentioned before the mashine grind runs over the shinogi

(b)

and even shows up in the shinogi-ji upper surface

(c)

of the blade.

Chu-kissaki

tip

& Mono-uchi

main cutting area of blade

(4)

&

(5).

The tip's cutting edge and blade's main cutting area mono-uchi are separated by the yokoto line and it is here that all blades bought have a very dull area of some 25mm. The cutting edge is so dull that one can actually press ones thumb on the edge and move it back and forth without risking injury.

The Yokote dividing line,

Tsuba

guard

(7)

&

(8)

The guard tsuba as well as the fuchi kashira are of the cast type and spray-painted black. This seems to be the norm now on all entry-level and more expensive models. Here the tsuba came with some unsightly scratches around the rim of the tsuba.

Conclusion

As is, the Raptor Series Shinogi Zukuri Katana (Entrance Level), is let down by a blade finish that is somewhat outdated and out-classed by its competitors. Shop on e-bay and you will see some well finished blades for under US$300 - or even less! Admitting, the steel used may be somewhat inferior to the 5160, but for cutting bamboo and tatami-omote, this would be more than adequate. The 5160 steel used for the Raptor Series, because of its contents; Carbon 0.56 - 0.64; Chromium 0.7 - 0.9 and Manganese 0.75 - 1, will be more resistant to cutting-edge failure and therefore more suitable for cutting into wood, metal or even steel.

However, in a dojo environment, where the cutting of mats/tatami-omote or green bamboo take is the set norm,

the Raptor fails to deliver.

Conclusion:

Functionality:

Cutting test on-

Seasoned full tatami omote

3

out of

10

Green bamboo take 40mm

6

out of

10

General practicality

4

out of

10

Quality:

Tsuba

7

out of

10

Fuchi, Kashira

7

out of

10

Tsuka and Tsuka-ito

9

out of

10

Saya

9

out of

10

Blade's finish

0

out of

10

Blade's sharpness

8

out of

10

Blade's yokote

0

out of

10

Blade's cutting edge

8

out of

10

Feel and handling

7

out of

10

Safety:

Two mekugi:

10

out of

10

After having re-worked/polished the original factory machine finished surface of the blade to an acceptable standard, the blade performed surprisingly well

Again, it should not be up to customers to re-polish or re-sharpen a new blade. This type of work is beyond most peoples scope and only leads, as in this case, to dissatisfaction and disappointment.

should have a distinct visual line without any physical protuberance (6) & (6a).

During any mechanised sharpening process this bulge could lift a tool just a fraction off the cutting edge leaving a blunt area on either side of the yokote; evident also on all the other Raptor blades we purchased.

Niku

, a blade's rounded convex profile.

To support a blade's cutting edge it needs to have niku (meat) behind it. The wider niku is, the stronger a blade becomes for cutting hard materials like bamboo or even metal. Less pronounced niku in a blade will make it slimmer and more suitable for cutting softer materials like mats tatami-omote. To be able to cut both materials successfully a blade's niku needs to be well balanced; too much niku and the blade will fail in cutting tatami-omote; not enough niku and a blade will fail to cut hard material like bamboo.

In case of the Raptor Shinogi Zukuri model niku is somewhat over-pronounced. This makes itself felt when cutting into soft target material and, with the blade's machine finish, it becomes very difficult to get a clean cut through a single tatami-omote. On the other hand, cutting through hard material like green bamboo, the blade performs reasonably well.

In comparison; an other blade in a similar price range had a well defined and clean shinogi line. (2a)